Custom Plastic Extrusion Manufacturer

Shaping Endless Possibilities® for over 55 Years

Formtech is a pioneer in the custom plastic extrusion industry. We created benchmark technologies used today by many firms in the industry. Our reputation has been built on creative innovation, technical expertise and reliability.

OEM’s of all sizes in a variety of industries appreciate our dedication to ensuring their needs are met. We help our customers discover the possibilities with material selection, design, and fabrication capabilities to deliver superior quality products at a competitive price.

Locations near Athens, GA and Erie, PA

We have two manufacturing plants producing custom plastic profile extrusions. Depending on your annual volume needs and tooling investment, we operate twin-screw (Georgia) and single-screw machines (Pennsylvania) to provide purchasing flexibility. In general, we provide:

- Single and twin-screw capabilities

- Multiple color and material extrusions

- Inline and offline services, such as embossing/texturing, tape application, punching & more

- State-of-the-art tooling

- Vacuum-calibrated water-cooled sizing technology

- CAD engineering and design assistance

- Prototype development

- Color matching

- Testing and quality control

Materials

With expertise from our material suppliers, we can help select the best material choices and properties for your application. In addition, we are able to design and prototype extrusions and assemblies for functionality, to consistently meet your specifications. Below are the primary raw materials we extrude.

- ABS

- ABS/ Glass fiber composite

- Acrylic

- Butyrate

- Flexible PVC

- Polycarbonate

- Polyethylene (HD, LD, LLD, MD)

- Polypropylene

- Polystyrene

- Rigid PVC

- TPR

- Wood plastic composite

Experience in a variety of markets

We work with customers in a variety of industries to optimize and add value for their products and production processes. Custom plastic extrusions are used in many applications, such as:

- Construction - windows, doors, siding, trim, HVAC

- Appliances - commercial and residential

- Electrical - power management, lighting

- Plumbing - tubing, pipes

- Interior - furniture, window treatments, flooring

- Retail - point of purchase, signage, displays

- Transportation - automotive, RVs, airplanes, roadways

- Agriculture - hydroponics, irrigation systems

- Marine construction - seawalls, bulkheads, piling

- Other industries - view additional custom extrusions

RELIABLE • QUALITY • EXPERTISE

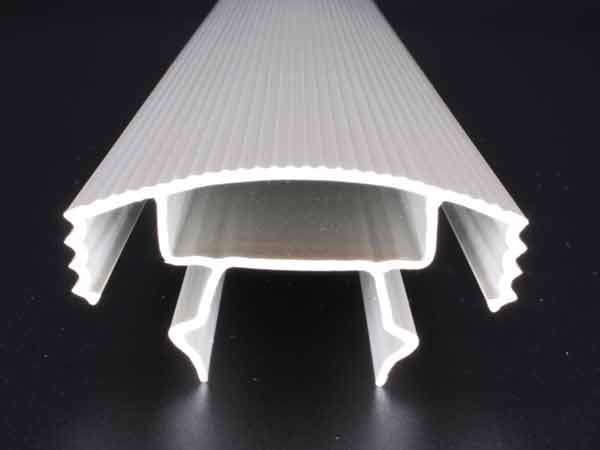

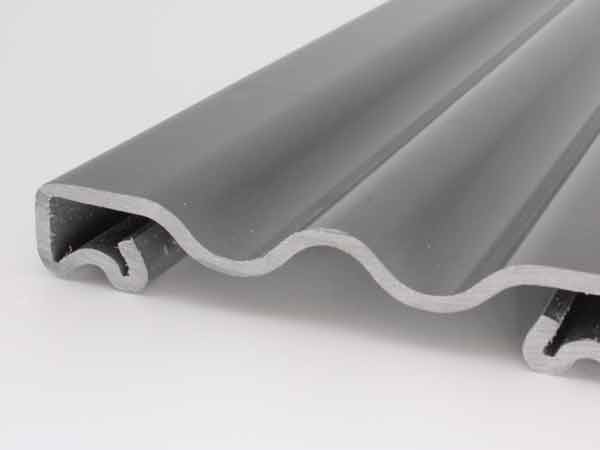

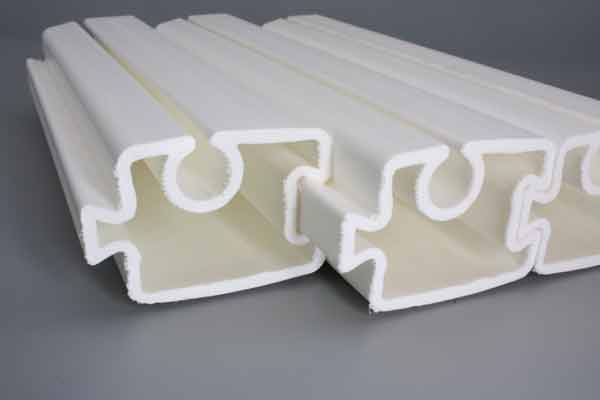

Complex Plastic Extrusions

We produce simple to complex co-extruded profiles with up to three different materials. Flexible or rigid PVC, recycled, or a variety of material choices and processes create products with multiple functionality.

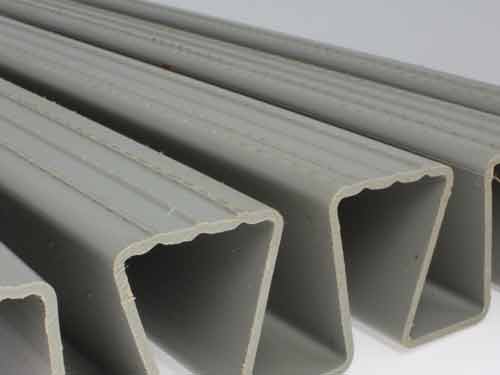

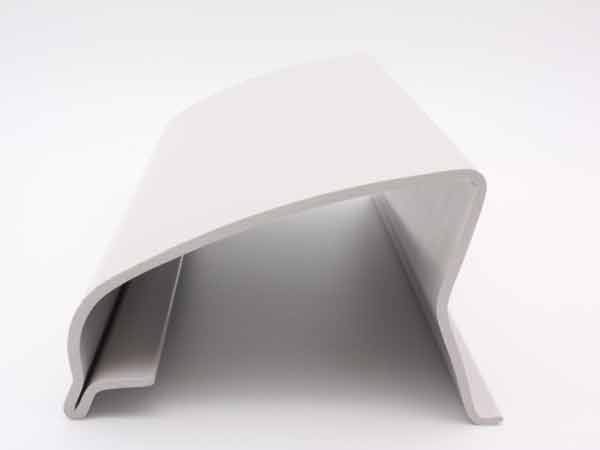

Small to Large Profiles

We extrude different sizes of profile shapes from small to large and in custom lengths. The smallest profile is 5.0mm and the largest is 12″w x 8″d (shown in photo). We can also coil or reel flexible profiles or tubing in long lengths.

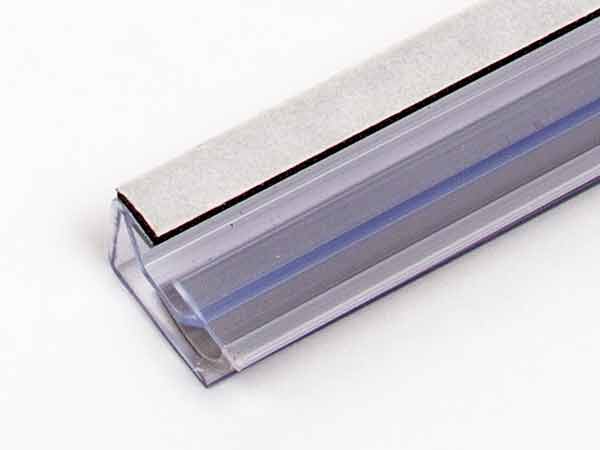

Inline & Offline Fabrication

Various fabrication techniques can be completed inline or offline. Some examples include wood grain patterns, tape application, punching, notching, slotting, tab creation, magnetic tape application, and drilling. Inline and offline fabrication of plastic extrusions can be helpful depending on the material properties, product function, volume (low or high), and delivery requirements, such as just-in-time.

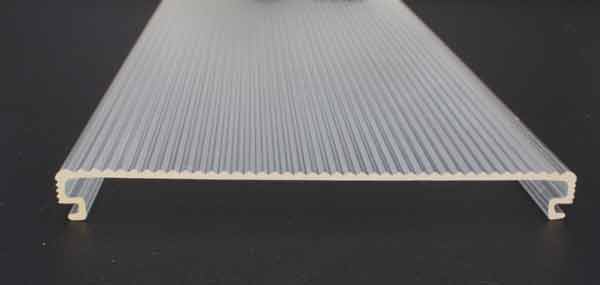

Clear Plastic Extrusions

We have expertise producing clear plastic extrusions with superior clarity. From wafer thin water clear lenses, to 1/8″ thick electrical components, our capability to process polycarbonate, acrylic, butyrate, and clear rigid PVC, offers an extensive range of possibilities in clear plastic resins. Clear plastic extruded profiles can include tubing, light lenses, electrical components, and more.